Consisting of immobilized activated carbon and cellulose fibers, Unifiltech's Nanopham C depth filter media provides superior adsorption characteristics over traditional stirred tank or packed bed carbon applications. Designed for use in a single-pass process, the large surface area of carbon to the process stream enables highly efficient color or odor removal. Unlike other depth filter media, designed for mechanical particle removal, Nanopham C depth filter media are designed for adsorption of colors, odors or other soluble contaminants.

Activated carbon is highly porous over a broad range of pore sizes, from cracks and crevices to molecular dimensions. It is this porosity that provides activated carbon's unique adsorptive properties. Generally, activated carbon contains surface areas in the range of 500-2000m²/gm. “Activation”refers to the development of the adsorption properties of carbon. Adsorption occurs when the organic molecules bond to the internal pores of the activated carbon. This happens in pores slightly larger than the molecules being adsorbed, which makes it extremely important to match the molecule being adsorbed to the pore size of the activated carbon.

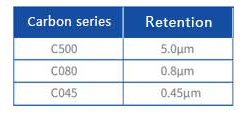

Careful blending of filter aids and cellulose fibers with activated carbon yields sub-micronic filtration and adsorptive treatments concurrently. Unifiltech manufactures carbon-impregnated media in a range of removal ratings and configurations. This provides standardization of carbon treatment in addition to simplicity and ease of handling and operation.

● Controlled Filtration

● Decolorization

● Deodorization

● Alcoholic Beverages

● PHarmaceutical API's

● Gelatins

● Fragrances & Oils

● Silicones

● Organic & Inorganic Acids

● Enzymes

The most accurate way to optimize your process is through laboratory scale testing. Samples of Nanopham C are available at no charge. Authorized Unifiltech representatives are equipped to run trials on-site, or product samples may be sent directly to Unifiltech for testing at our in-house laboratory.

All filter pads are manufactured to very high standards for a wide range of

applications in the pharmaceutical, chemical, cosmetic, electric utility and food and beverage markets. Unifiltech also offers a Validation Guide to assist in the validation of its filter pads in your process. The Validation Guide contains information regarding raw materials, extractables, and general information about the product.

● For detailed applications and filtration products, please contact Unifiltech Technical Supports and Sales Engineers.

Copyright © 2020-2030 Jiangxi Unifiltech Technology Co,.Ltd沪ICP备19000561号-1